PRODUCTS

Tumbling fluidized bed granulating-coating Machines (Multiplex Coater)

MP Series

Compliant with the production of pharmaceuticals and chemicals

High-quality coating

-

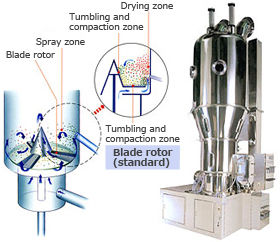

These granulator/coater with fine particle coater combine the features of fluidized bed granulators (powder particle fluidization and highly efficient drying effects by air flow) and agitating granulators (powder and particle fluidization, tumbling, and compaction effects by mechanical force).

-

Capable of mixing, granulating, coating, drying, and cooling processes in a single machine, the MP series improves productivity and prevents contamination.

Granulate heavier particles with narrow size distribution, thus resulting in uniform coating. -

The tangential spray installed in the lower section enables efficient film coating and masking processes of granules particles that have been considered difficult to achieve.

-

Production time saving by the Twin Shaking system.

Feature

-

The introduction of the blade rotor has enabled the flow control of difficult-to-fluidize particles and heavy particles, which has been difficult on conventional fluidized beds, and accordingly leading to easy control of granulation and coating processes.

-

Efficient and dense coating is achieved by spraying to a high particle density zone with a tangential spray.

Compliant with the production of pharmaceuticals (GMP). -

Easy to install various types of measuring instruments (for particle size distribution measurement, near-infrared spectroscopy, etc.) that support process analytical technologies and real-time quality monitoring.

-

Measures are taken to secure safety: installation of an explosion vent and a grounding wire sewed into the filter unit.

-

The adoption of twin filters allows adhered particles to be blown off the filter without stopping the flow, thus resulting in high productivity.

-

Equipped with automatic cleaning system.

Tumbling fluid bed granulator Dryer / Coater System

MP-01

Compliant with the production of pharmaceuticals and chemicals

High-quality coating

-

Realizes wide range of particle processing to meet the various applications by replacing granulation vessel, the blade rotor, the fluidized bed vessel

-

Experience as research and development field in a wide range of industries including pharmaceuticals, foods and battery materials

-

As a new option, it is possible to install agitating and mixing granulator unit(VG unit)in existing MP-01 unit.

The classification according to diameter of a particle

MP

Feature

Equipped with a proprietary rotary disc with blades, one unit serves as a multi-functional machine that performs mixing, granulation and coating.

The power is subjected to the rolling compaction by the blade rotor in the fluid bed and dried eith the hot fluid air at the periphery, which makes the granulation/coating of highly adhesive/cohesive powders possible, while these powders cannot be processed with other fluid bed machines.

Applications

(Pharmaceutical drugs)

Granules for tableting, fine granules for preparation, coating(bitterness masking, color coating, controlled release coating, enteric coating)

(Food)

Granulation of functional food, granules for tableting, fine granules for preparation

(Powder metallurgy and batteries)

Ferrite, powders for MIM molding, powders for SIM molding, carrier, toner, carbon, primary batteries, secondary batteries

SFP

Feature

Equipped with a swirl fluidizing system to reduce the height of powder fluid bed, this processor can be used for the process requiring high inlet air volume and high spray rate.

The processor requires a less coating time than conventional fluid bed machines.

Equipped with the “particle crushing and sizing mechanism plus hybrid fluid bed,” the mechanical control is enabled other than the conventional operation control that uses air and heat.

Applications

(Pharmaceutical drugs)

Granules for tableting rapidly oral disintegrating drugs, granules for tableting, fine granules for preparation, coating(bitterness masking, color coating, controlled release coating, enteric coating)

(Food)

Functional food granulation, granules for tableting, fine granules for preparation, bitterness coating

(Powder metallurgy and batteries)

Ferrite, powders for MIM molding, powders for SIM molding, carrier, toner, carbon, primary batteries, secondary batteries

SPC Improved Wurster

Feature

Wurster equipment has a long-term proven track record. We have uniquely enhanced the equipment by installing the system that sprays powder upward from the bottom of fluid bed to meet the requirement of fine particle coating process of bulk pharmaceuticals.

(JP Patent: No.3352059)

This processor is capable of processing various granules as shown in practical use for manufacturing process of bitterness masked oral disintegrating drugs.

Applications

(Pharmaceutical drugs)

Oral disintegrating drugs, granules for tableting, fine granules for preparation, coating(bitterness masking, enteric coating, controlled release coating)

(Food)

Functional food granulation, granules for tableting, fine granules for preparation

(Powder metallurgy and batteries)

Ferrite, powders for MIM molding, powders for SIM molding, carrier, toner, carbon, primary batteries, secondary batteries

FD

Feature

A spray type processor used for general granulation and simple coating.

Equipped with the system that sprays powder from the top of fluid bed, this processor is most suitable for granulation for pharmaceutical drugs, food, and feed, agricultural chemical and fertilizer coating, and taste masking/moisture-proof coating of pharmaceutical drugs.

Applications

(Pharmaceutical drugs)

Granules for tableting, fine granules for preparation

(Food)

Functional food granulation, granules for tableting, fine granules for preparation

(Powder metallurgy and batteries)

Ferrite, carrier, toner, carbon, primary batteries, secondary batteries, agricultural chemicals, fertilizers

Tumbling fluid bed granulator Dryer / Coater System for small quantities

MP-Micro

-

Newly released more compact design (working capacity is 60ml.)

-

Fine particle coating is realized with even smaller quantities of product (the order of tens of grams) than our Multiplex MP-01.

-

Tumbling motion by rotor enables optimum layering and fine particle coating.

-

As a multi-functional processor, granulation and drying are also available.

POWREX CORPORATION

Head Quarters 5-5, Kitagawara 5-chome, Itami-city, Hyogo-pref., 664-0837, Japan Phone: +81-72-778-7301 (Main)

Tokyo Branch Kandasudacho Place 6F,1-9 Kandasudacho,Chiyoda-ku,Tokyo 101-0041, Japan

Toyama Office Tamura Building, 5-24 Sougawa 1-chome, Toyama-city, Toyama-pref., 930-0083, Japan

.jpg)

.jpg)

Copyright(C) 2024 powrex corp.all right reserved